Home

Service Details

Why Choose GFRP Rebar,

For Stronger GFRP Tunnels & Underground

What Is GFRP Rebar?

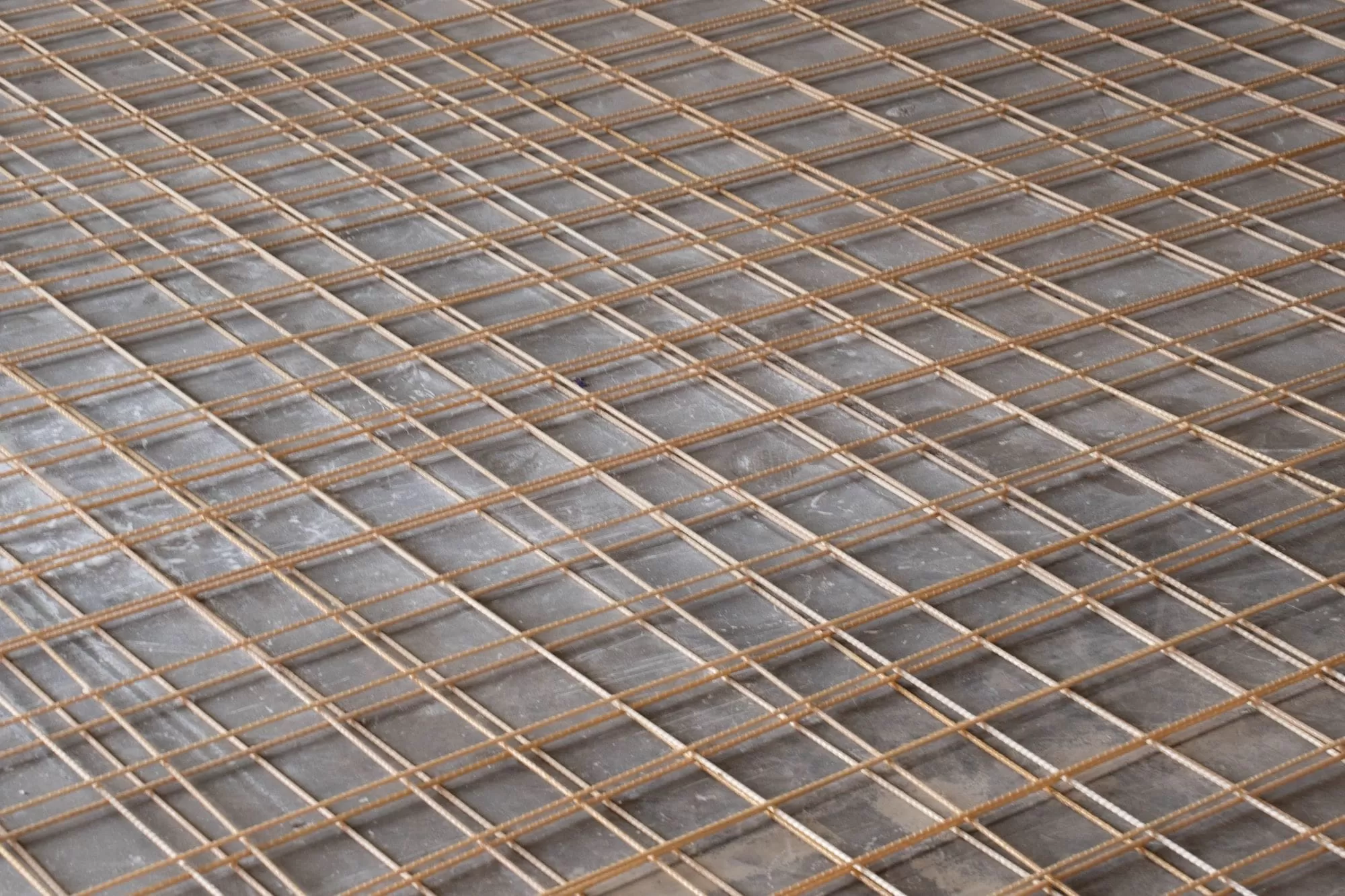

Glass Fiber Reinforced Polymer (GFRP) rebar is a next-generation composite reinforcement solution developed to replace conventional steel rebars in modern infrastructure projects, including GFRP rebar for tunnels and underground structures. Manufactured using high-strength glass fibers combined with durable polymer resins, GFRP rebars deliver superior corrosion resistance, lightweight handling, and extended service life.

In regions like India, where underground and tunnel infrastructure is exposed to moisture, chemicals, and confined environments, traditional steel rebars corrode rapidly. GFRP rebars eliminate corrosion-related failures, making them ideal corrosion resistant rebars for tunnels and reliable non-metallic reinforcement for underground structures, ensuring higher durability, lower maintenance, and long-term cost savings.

- Cost-effective over the structure’s life cycle

- High tensile strength with significantly lower weight

- 100% corrosion and rust resistant for tunnel environments

- Low maintenance with extended service life

- Suitable for tunnels, underground concrete, and infrastructure projects

Advantages of GFRP Rebar in Tunnels & Underground

Non-Conductive & Electromagnetically Neutral

GFRP rebar for tunnels is non-conductive and electromagnetically neutral, making it ideal for underground environments with electrical wiring, rail systems, signaling networks, and power tunnels. Unlike steel, non-metallic reinforcement for tunnels eliminates electromagnetic interference and improves operational safety.

Corrosion Resistance & Long-Term Durability

Underground structures face constant exposure to moisture, chemicals, and aggressive soil conditions. Corrosion resistant rebar for tunnels such as Glass Fiber Reinforced Polymer (GFRP) rebar is completely rust-free, ensuring extended service life and significantly reduced maintenance costs.

Lightweight with High Strength-to-Weight Ratio

GFRP bars for underground construction are nearly 75% lighter than steel while delivering excellent tensile strength. This simplifies transportation and installation in confined tunnel spaces, accelerating project timelines.

Improved Safety for Underground Infrastructure

The combined benefits of non-corrosive, lightweight, and non-conductive properties make FRP rebar for underground infrastructure the safest choice for metro tunnels, underground bridges, mining shafts, and utility corridors.

Key Applications of GFRP Rebars

Highway, Expressway & Rigid Pavement Construction

GFRP rebar for highway construction is increasingly used as a corrosion-resistant alternative to steel reinforcement in rigid pavements and expressways. As non-metallic reinforcement bars, GFRP rebars prevent cracking caused by corrosion, moisture ingress, and de-icing chemicals, resulting in longer pavement life, reduced maintenance cycles, and lower lifecycle costs.

Bridge Decks, Flyovers & Elevated Road Structures

In aggressive environments such as coastal regions, urban flyovers, and high-traffic corridors, GFRP reinforcement bars provide superior durability compared to steel. These glass fiber reinforced polymer rebars resist chloride attack, humidity, and chemical exposure, ensuring long-term structural performance for bridge decks and elevated road sections.

Road Rehabilitation, Retrofitting & Overlay Projects

For rehabilitation and strengthening of existing infrastructure, GFRP rebars offer a lightweight yet high-strength solution. Their low weight minimizes additional dead load, making them ideal for retrofit and overlay applications where corrosion resistant rebars are required without increasing structural stress or reconstruction costs.

Why GFRP Is a Smart Choice for Tunnel & Underground Infrastructure in India

Across India, tunnels and underground structures are exposed to moisture, chemicals, and aggressive soil conditions that accelerate corrosion in traditional steel reinforcement. This leads to frequent repairs, higher maintenance costs, and reduced service life of underground infrastructure.

Glass Fiber Reinforced Polymer (GFRP) rebar offers a durable solution for tunnel construction and underground concrete reinforcement. As a non-metallic reinforcement for tunnels, GFRP rebars are completely corrosion resistant, lightweight, and designed for long-term performance in confined underground environments.

With lower life-cycle costs and superior durability, GFRP rebar for underground infrastructure is increasingly adopted as corrosion resistant rebar for tunnels, supporting India’s move toward resilient, sustainable, and long-lasting underground construction.

Conclusion

GFRP rebar for tunnels and underground structures is a proven, next-generation solution designed to replace steel in demanding environments. As glass fiber reinforced polymer rebar, GFRP delivers exceptional corrosion resistance, lightweight handling, and long-term durability for underground tunnel reinforcement materials.

Used as GFRP reinforcement for underground infrastructure, these non-metallic rebars for underground projects eliminate corrosion-related failures and reduce lifecycle costs. Corrosion resistant rebar for tunnels such as GFRP ensures reliable performance in metro tunnels, utility corridors, and subsurface concrete applications.

For future-ready construction, choose FRP rebar for underground construction. Partner with Tets RebarX for trusted, high-quality GFRP solutions.

CONTACT NOW